Boxed Packaged Goods: The Ultimate Guide To Sky Rocket Your Business

Boxed packaged goods assist your business with developing quickly. The use of packaging products in supply chain industries can make the job easier. Most well-known logistics companies now use box packaging. Few business models generate more profit in a short period, and the packaging business is one of them.

Do you remember how it felt when you picked up your first iPhone? Remove the plastic seal and feel the smooth white box? When you first touch the box, you already feel the importance, quality, and value of this device. This is no coincidence! Apple has thought carefully about how we package our products to fit their brands, providing the ultimate in product packaging innovation and consumer convenience.

Your company today is moving at a frightening pace. A company’s personality evolves and this can help to maximize your brand image. Bundling is turning into an inexorably significant part of business today. Boxed Packaged Goods assist your organization with development. Packed Boxed Packaged Goods in the supply chain can make the job easier. Currently, most well-known logistics companies use box packaging.

Topics, we will be covering in this blog of Bagged Packaged Goods are:

- Types of Goods Packed in Bags

- Types of Boxes

- Types of Packaging: Primary, Secondary, and Territory

- What are the benefits of boxed packaged goods?

- Things to watch out for a while boxed packaged goods

- Boxed packaged goods are important.

Types Of Goods Packed In Bags

There are several types of Boxed Packaged Goods that require proper packaging.

- Cloth

- Approximately

- Electronic Products

- Jewel

- Perfume

- Food Boxes

Types of Boxes For Packaging

Boxed Packaged Goods is a popular packaging material, including bags, boxes, or containers, that manufacturers sell to third parties for use in their projects. These materials also come in a variety of shapes, sizes, and colors. Boxed Packaged Goods can be used for all applications, large and small. For example, it can be used for grocery bags, printed mugs, clothing bags, cosmetic bags, gift boxes, toy packaging, etc.

Here, we will be dealing with the 6 different kinds of boxes for Boxed Packaging Boxes:

- Cardboard Boxes

- Rigid Boxes

- Clipboard Boxes

- Corrugated Boxes

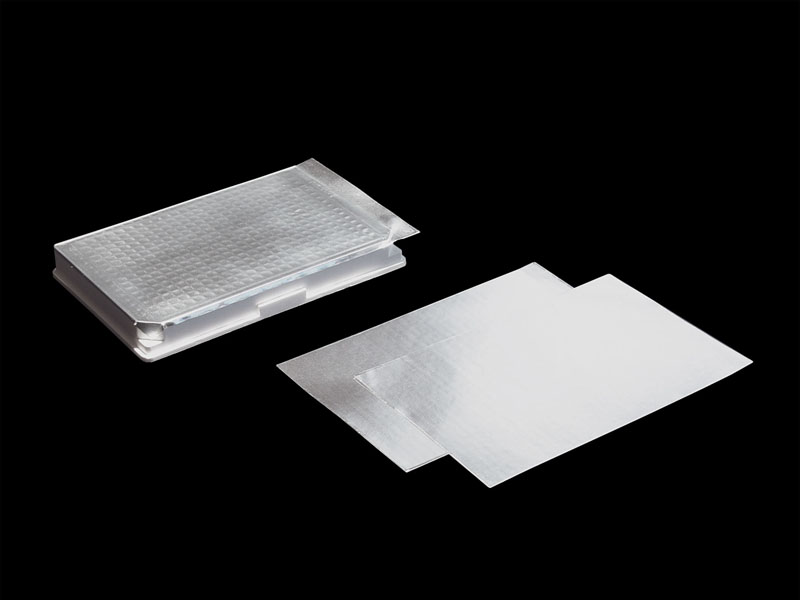

- Foil Seal

- Wooden Boxes

1. Cardboard Boxes

Cardboard boxes are made of thick cloth-based material that weighs over 250 gsm. Cardboard boxes are very attractive and ideal for retail use. Corrugated boxes for waterproofing and durability are easy to print and laminate. Cardboard packaging features exquisite shapes and decorations to promote and decorate boxed goods and increase competitiveness. Packaging of paper products is the most common type of packaging for industrial bagged packaged goods. Cardboard boxes are the most basic form of shipping cute packaging, and cardboard boxes are widely used as sales packaging for various products. Suppliers use paper cartons for food, pharmaceuticals, and electronic products.

Advantages

1. This box is very flexible.

2. Easily make boxes of various shapes and sizes.

3. Very light.

4. Easy to print and flexible packaging design.

5. Easy to recycle.

6. Best for all kinds of bagged packaged goods ranging from food to electronics.

Disadvantages

1. Not for heavy products

2. May Get Deformed

3. Not best for weatherproofing

2. Rigid Boxes

Rigid cartons consist of cardboard compressed to very small dimensions and are four times thicker than conventional folding cartons. Designed to test high-quality products in the usual folding cartons of boxed packaged goods.

Rigid boxes are made of thick cardboard that is four times thicker than the cardboard used to make standard folding boxes. These packaging items are best suited for electronic devices. Custom Product boxes cannot be shipped directly to you in this type of packaging. At least one outer carton is required for shipping. The simplest real-world example of a hard box is Apple’s iPhone and iPad boxes, which are two-piece hard/branded boxes.

Advantages

1. Setup is quick.

2. These packaging will not fall off.

3. Much more durable in appearance and material.

4. Beautiful and smooth outer surface, nice to the touch.

5. Simple elegance – no complicated graphics required.

Disadvantages

1. Expensive

2. Usually not summed

3. Instead of using separate packaging, it is usually packaged with additional shipping/export packaging to protect the product.

Also read: 10 Best Benefits Of Online Learning For Students And Teachers

3. Clipboard Boxes

Clipboard boxes are a type of cardboard that should not be confused with Medium Density Fibreboard (MDF). In a process similar to MDF, cardboard is made from recycled paper (instead of wood), which is pressed together into the cardboard and bonded with an adhesive or resin.

It is ordinarily available in two tones, brown or white, and its fortitude depends upon the thickness of the chipboard. The higher the thickness, the more grounded and harder it is; however, it doesn’t ordinarily move toward the solidness level of a strongbox. Printing is also possible if the finishing material is available.

Cardboard sheeting is a lightweight material from which numerous items are made, for example, grains, saltines, napkin boxes, and so on. So, if your business handles heavy items, cardboard packaging cannot be used. Also, if the storage environment is very humid, the chipboard can come loose easily, leading to discoloration and swelling.

These are primarily used for POP applications and display purposes. Chipboard packaging is mainly used for packaging toothpaste, medicines, and perfumes.

4. Foil Seal

Foil Seal is for small items, usually food, as well as clothing, textiles, and certain delicate items such as computer HDDs and silicon chips. Used as a package. (RAM set, etc.). They are PET foils with a layer of aluminum foil, a large number of which have a metallic base tone, yet it is likewise conceivable to print a brand on them.

Foil seals help keep the custom product packaging firm to maintain its taste, protect it from bacterial invasion, and extend shelf life. In addition to food, film-sealed bags are also used to wrap bedding and clothing. This process removes oxygen from the bag to secure the tissue and prevent the growth of fungi and other bacteria. Nuts, muesli, smoked fish, cheese, and sausages are also packed in foil-sealed bags to prevent spoilage.

Advantage

1. An anti-static bag is the best packaging material for electronic component PCBs that removes static electricity from the PCB and prevents damage.

2. It is additionally conceivable to print the brand.

3. 100% vacuum airtight to the external environment, providing complete protection from moisture, dust, and other sources of pollution.

Disadvantage

1. Plastic is not the most eco-friendly option, and the foil lining makes it difficult to recycle these bags with other plastics.

2. Not suitable for premium products as it is related to simple food packaging.

3. It cannot be protected from impact, dropping, crushing, etc.

4. Not suitable for fragile or rectangular items

5. Wooden box

Are you searching for small business packaging ideas? Then, this wooden custom box packaging can be the best custom packaging for small businesses. Speaking of wood, it’s so difficult to carry that many people don’t consider it an easy-to-drink material. However, for delicate items such as glass, wooden boxes are the most durable package.

You can also store your electronics in wooden boxes as they are the best option for packing your electronics. The wooden box also gives it a naturally stylish and sophisticated look. The only downside is that if not properly cared for, it can grow mold and can be quite expensive.

Wood packaging boxes are often attached with flannel, EPE, paper, sponge, and foam to protect the items inside from collision. Due to the exquisite selection of materials, quality, and accessories, the price to pack in wooden boxes is higher than other packaging materials.

Carton makers only occasionally make cases utilizing logs rather than compressed wood and fibreboard. While reducing costs, quality packaging is on par with log products.

Three Types Of Packaging: Primary, Secondary, And Territorial

When a company packs its products, it is important to be able to differentiate between these levels of packaging, as each level is suitable for different types of products. Different levels serve different purposes and not all are intended for the same users or consumers. Regardless of the packaging type, finding the right balance between the different packaging levels is important to effectively store and protect your product.

Primary Packaging

Primary packaging is packaging that comes in direct contact with the product itself, sometimes referred to as a consumer unit. The primary purpose of primary packaging is to contain, protect and/or preserve the finished product, in particular from contamination.

Secondary Packaging

This type of packaging is used to create inventory items commonly referred to as SKUs by grouping a certain number of products outside of their primary packaging. This makes it easier to work with, combining small products into one package.

Tertiary Packaging

This type of packaging, also known as bulk or shipping packaging, is used to group large numbers of SKUs for shipment from point A to point B (e.g., from a manufacturing facility to a point of sale). At this stage, products are processed into distribution units.

Also read: What Are Interpersonal Skills And Why Do They Matter?

What Are The Benefits Of Boxed Packaged Goods?

With Boxed Packaged Goods, you can make a good business deal for your business and make a good profit. The box contains everything the customer needs while packing and shipping. In most cases, boxes contain personal care products such as lotions, cosmetics, medicines, and other items.

Custom packaging or packaging products with special effects and attractive designs will impress buyers and this is exactly what you need. When shoppers see an attractive shipping box, they want to buy immediately, and you can expect a lot of traffic from your store.

Items may be lost or damaged in transit if not properly packaged. Besides, good packaging serves to protect the product.

Things To Watch Out For While Packaging

The question often arises about how to package a product. The right steps and methods of the packaging process can make a big difference. No matter what product you need to ship, you can count on it to arrive at your destination exactly as it was delivered. To ensure product safety, every company must take several important steps when packaging.

Always follow these 7 steps to ensure your product is perfectly packaged!

1. Know your target audience

2. Make your package unique

3. Create amazing unboxing experiences

4. Use a green design to enhance your brand image

5. Find box design ideas

6. Put the handwritten shipping label on boxes

7. Make sure the product supplier understands the boxed packaged goods shipping requirements.

Boxed Packaged Goods Are Important.

Boxed packaged goods merchandise is really important to product safety and to impress shoppers. If bagged packaged goods are not properly, handling in the warehouse, in transit, and during shipping is difficult. Packaging helps warehouse and sales staff with items such as handles or various items to help simplify the handling of goods.

Also Read: Dayforce Trader Joes